Laser Marking

BUDIT® L Series: Laser marking and welding ingredients

Laser marking is widely recognized as one of the most effective technologies for the marking and coding of plastics and offers a multitude of solutions for a wide range of markets. Many plastics have poor absorbing properties; some are even transparent for laser light. The BUDIT® L creates excellent results in processing speed, marking contrast and strength of welding seams. Budenheim uses formulations which are based on eco-friendly ingredients avoiding suspicious materials like antimony. This makes it safe for medical and food contact applications.

The BUDIT® L Series offers an innovative laser marking pigment with

extraordinary selective absorption in the NIR. This is accompanied by a

high transparency in the visible range. The product is designed for Nd:YAG

lasers at a wavelength of 1064 nm.

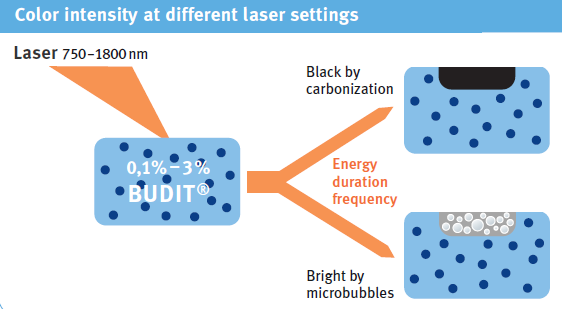

Depending on the energy level, different visual marks, from bright to dark,

can be generated on the polymer surface. Due to low dosages, BUDIT® makes

the marking of transparent polymers possible.

Using typical concentration with 0,1%– 5% of BUDIT® L, the energy of

the laser beam creates marks within 10 μm underneath the plastic surface.

Depending on the laser parameter the absorption causes two processes:

* The laser causes a degradation of the pigment and the polymer creates

the dark marking color. For high thermostable polymers, the degradation

of the pigment can be controlled till the conductive surface is built up.

* Conversion of the beam energy into heat, combined with little gas release,

creates microbubbles. Depending on the process parameters, the visual

appearance can be tuned to bright instead of black.

The chemical basis of Budenheim laser active pigments is purely inorganic.

The material is eco-friendly and complies with the strictest standards.

Employing neither antimony nor other critical substances, BUDIT® is safe

for medical and food contact applications.

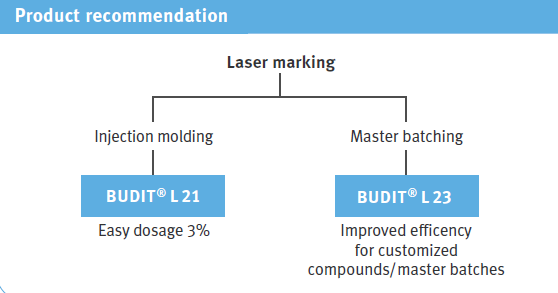

Powder product can be difficult in processing especially in small dosages.

Therefore, BUDIT® L is designed as a single pigment concentrate with

a high amount of the functional pigment based on a universal carrier.

For a master batcher as well as compounders, it is easy to carry over

a pigment and to produce a final master batch with specific target color

and additives.