Flame Retardants

| For Non-Halogenated additives <and solutions:

Ammonium Polyphosphates for Paints and Coatings—FR CROS range Ammonium Polyphosphates for Plastics and Polymers– Budit 6 series and Budit 3 series For Halogenated Systems: Goldflam Antimony Trioxide |

Ammonium Polyphosphate

Mineral & Chemical Services are the exclusive UK distributor for Budenheim’s range of halogen free flame retardant additives.

For Paints and Coatings

Intumescence

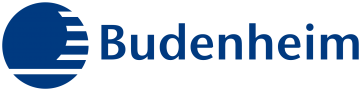

Our range of flame retardant additives are based on the mechanism of intumescence. An intumescent paint or coating will foam up to create an insulating carbon based char which protects and slows the heating of the material it is applied to. The protective layer also prevents smoke release. Intumescent coatings begin to foam and carbonise at about 200 ºC to create a thermally insulated layer. This can delay the rise to the critical temperature limit by several hours.

Intumescence requires three main ingredients:

ACID SOURCE— Catalyst for the intumescence, Ammonium Polyphosphate

CARBON SOURCE—a base for the char, usually a polyalcohol such as pentaerythritol.

BLOWING AGENT—blows/bubbles the carbonaceous char from the surface causing a foam.

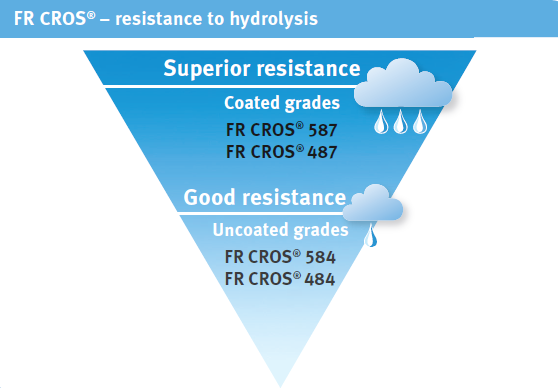

We specialize in supplying various grade of ammonium polyphosphate and complimentary products. Ammonium polyphosphates are key ingredients of intumescent coatings. They act as charring catalysts and influence the performance and stability of the finished coating. Regardless of the high moisture content in the airports of Singapore or the sunny, dry climate of Arizona, Budenheim’s FR CROS® specialties can perfectly match to a wide range of coating requirements. Ammonium polyphosphates ensure stable foaming and protect steel structures from collapsing. In addition, oxygen transmission is prevented and the spread of toxic fumes during the fire are inhibited. The use of FR CROS® leads to non-toxic, environmentally-friendly fire protection. Choosing the correct APP is important.

FR CROS® Series: Fire Protective Ingredients

Intumescent coatings are the ideal fire-protection solution for applications such as paints and coatings on the steel structures of buildings. FR CROS® ingredients and special compounds ensure the best incorporation into the various coating matrices. Ammonium polyphosphates (APP) are key ingredients for intumescent coatings. They act as charring initiators and influence the performance and stability of the finishing coating. The functional coated grades combine the compatibility to various coating matrices designed for different requirements. FR CROS® intumescent ingredients combine different multiple functional components for steel, textile, wood coatings, sealants and adhesives (FR CROS® 484, 585 and surface coated FR CROS® 487 and 587). FR CROS® char improvers enlarge the fire protection.

For Polymers

BUDIT® 3 Series and BUDIT® 6 Series: Halogen-free flame retardant ingredients and systems

Researchers at Budenheim have developed three major routes to attack fire: intumescent systems, char formation synergistic with gas phase activity and unflammable dripping. The full product range of BUDIT® flame retardants covers the entire application spectrum within engineering plastics (e.g. PA, PBT) as well as polyolefins (e.g. PE, PP). BUDIT® 3 Series provides Chemical components for creating sophisticated flame retardant formulations in order to precisely adjust flammability in certain applications. The BUDIT® 6 Series provides ready to use systems that are designed for direct use in plastics, extrusion and injection molding.

Antimony Trioxide

| Antimony Trioxide (Sb2O3) is used as a synergist to halogen based flame retardants.

Halogen based systems work in the gas phase. When a fire is burning, the energy is so great that the fuel and water produced in the combustion reaction are broken down further into more reactive free radical species. In fire, halogenated flame retardants release less reactive radicals and react to give non-combustible gases decreasing the fuel for the fire to burn further. Antimony Trioxide forms halogen halides and oxyhalides which are highly volatile and transport the halides into the gas phase. |